How to go through the Refrigerant booster pump customization?

2021-02-02

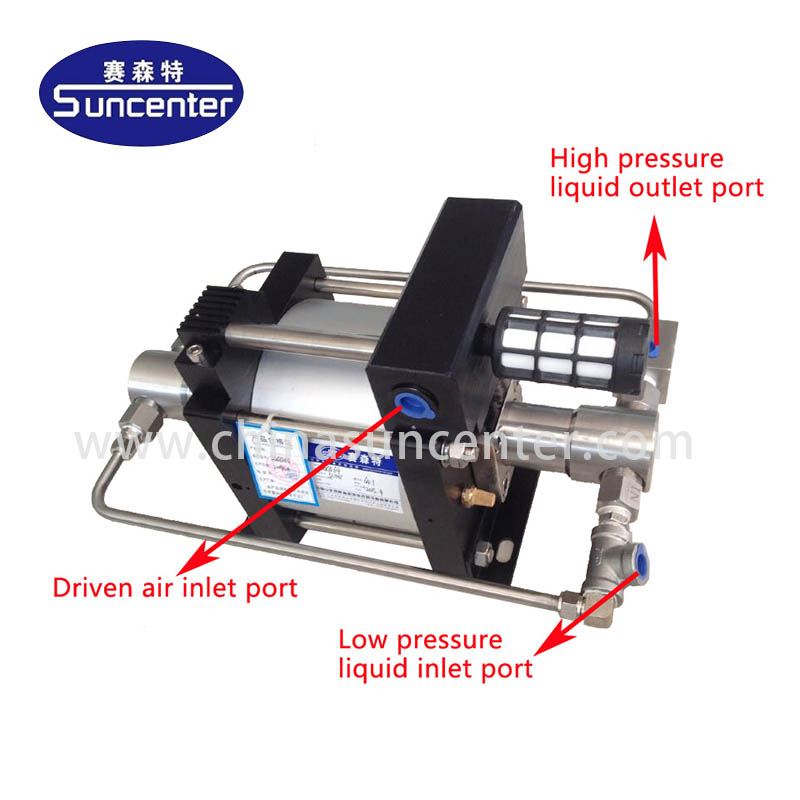

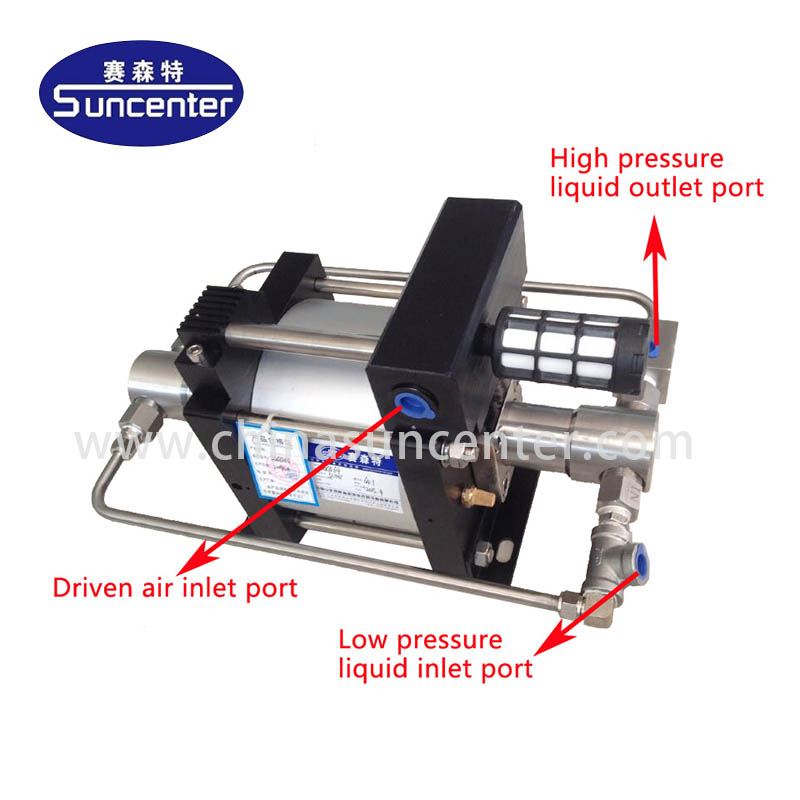

Just let Dongguan Suncenter Fluid Control Equipment Co., Ltd know your requirement. Because of our experience, we will take you through the entire process, from cost volume analysis through to design, tooling and manufacturing. Choose from an array of factors to create the perfect Refrigerant booster pump or solution based on your requirements. No matter what requirements you make, we have the first-class designers and R&D professionals ready to bring your idea into reality. We have years of experience creating classy product designs that will help to set your brand apart.

Suncenter Fluid Control Equipment takes the leading position of China in the field of haskel pump production. According to the material, Suncenter Fluid Control Equipment's products are divided into several categories, and hydrostatic testing is one of them. This product causes only a small amount of noise pollution. It uses a fundamental method to control noise - eliminating friction as much as possible. Its seal systems are designed for a long working life. I used to concern that the heat generating by the mechanical equipment will damage the seal parts, but it proved that it is totally not affected by the heat. - Said one of our customers. Its operation is safe with no heat, flame or spark risk.

Our company bears social responsibility. We have approaches to reducing carbon footprint ranging from designing next-generation products to working proactively to achieve zero waste to landfills by investing in state-of-the-art equipment into recycling the clean waste from production.

Suncenter Fluid Control Equipment takes the leading position of China in the field of haskel pump production. According to the material, Suncenter Fluid Control Equipment's products are divided into several categories, and hydrostatic testing is one of them. This product causes only a small amount of noise pollution. It uses a fundamental method to control noise - eliminating friction as much as possible. Its seal systems are designed for a long working life. I used to concern that the heat generating by the mechanical equipment will damage the seal parts, but it proved that it is totally not affected by the heat. - Said one of our customers. Its operation is safe with no heat, flame or spark risk.

Our company bears social responsibility. We have approaches to reducing carbon footprint ranging from designing next-generation products to working proactively to achieve zero waste to landfills by investing in state-of-the-art equipment into recycling the clean waste from production.

custom_message