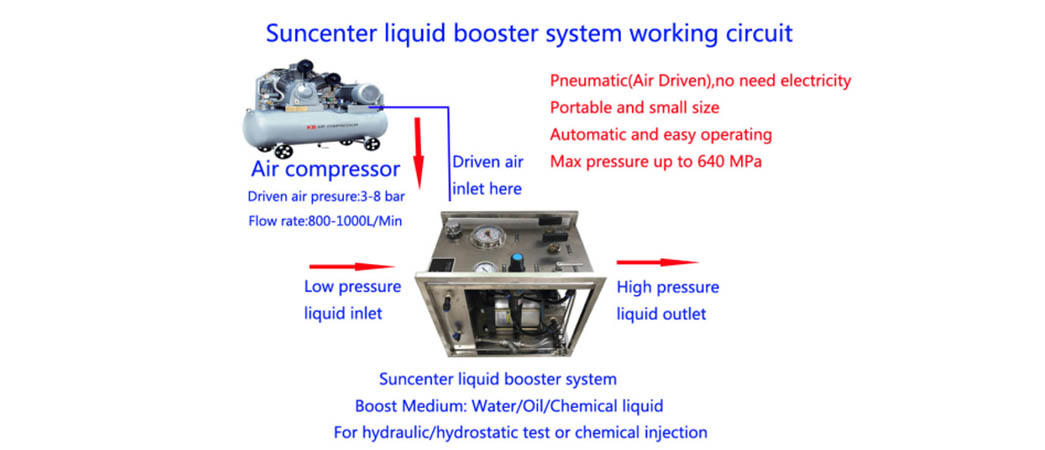

Suncenter Oilfield chemical reagent injection system Pneumatic chemical reagent injection booster system

Chemical reagent injection system is widely used in the world oil production and processing industry. Using the Air / gas driven system to filling chemicals to the oil wells, gas wells and pipelines, restore the normal work of the oil (gas) well, also can be used for delivery of raw materials to the high-pressure reaction kettle quantitative.

The effect of the chemical injection system is to use a chemical injection system to return or inject a liquid chemical agent into the fluid at high pressure or low pressure. To return fluid injection of chemical agents usually using methanol, preservatives, deoxidizer, drilling fluid additive (caustic soda and liquid polymer) and defoaming agent. Chemical injection system is a relatively simple system, its suction end is using pneumatic piston pump, the pump and chemical agents are connected to the container. And the discharge end is directly connected with the pipeline.

Equipment characteristics

◪ Equipped with high quality pneumatic chemical reagent injection pump, can easily achieve the output pressure and flow of any adjustable, controllable;

◪ The contact liquid section is stainless steel, strong corrosion resistance, suitable for a variety of chemical reagents; (also can use the gas system)

◪ It can be used in a variety of pressure level of the wellhead, the system with the function of the pressure starting;

◪ Chemical reagent injection system output pressure is high, 6.0-640 MPa is arbitrary, the system has to stop working under the set pressure;

◪ Advanced technology, reasonable structure design. The features of small size, light weight, beautiful appearance;

◪ By air/gas driven, no need to use electricity, there will be no spark generated, safe explosion-proof;

Model | Pressure Ratio | Driven air pressure PL | Formula to calculate outlet pressure | MAX Outlet | Driven | High pressure Outlet port | MAX Flow |

DLS-GD6 | 6:1 | 3-8 bar | 6XPL | 48 | G 1/2 | NPT/ZG | 48.60 |

DLS-GD10 | 10:1 | 3-8 bar | 10XPL | 80 | G 1/2 | NPT/ZG | 30.61 |

DLS-GD16 | 16:1 | 3-8 bar | 16XPL | 128 | G 1/2 | NPT/ZG | 19.73 |

DLS-GD28 | 28:1 | 3-8 bar | 28XPL | 224 | G 1/2 | NPT/ZG | 11.30 |

DLS-GD40 | 40:1 | 3-8 bar | 40XPL | 320 | G 1/2 | NPT/ZG | 7.69 |

DLS-GD64 | 64:1 | 3-8 bar | 64XPL | 512 | G 1/2 | NPT/ZG | 4.94 |

DLS-GD80 | 80:1 | 3-8 bar | 80XPL | 640 | G 1/2 | NPT/ZG | 3.96 |

DLS-GD100 | 100:1 | 3-8 bar | 100XPL | 800 | G 1/2 | NPT/ZG | 3.13 |

DLS-GD130 | 130:1 | 3-8 bar | 130XPL | 1040 | G 1/2 | NPT/ZG | 2.40 |

DLS-GD175 | 175:1 | 3-8 bar | 175XPL | 1400 | G 1/2 | NPT/ZG | 1.81 |

DLS-GD255 | 255:1 | 3-8 bar | 255XPL | 2040 | G 1/2 | NPT/ZG | 1.23 |

DLS-GD400 | 400:1 | 3-8 bar | 400XPL | 3200 | G 1/2 | NPT/ZG | 0.79 |

Pneumatic chemical reagent injection pump system-DLS series

◪ The hottest selling Model C cabinet

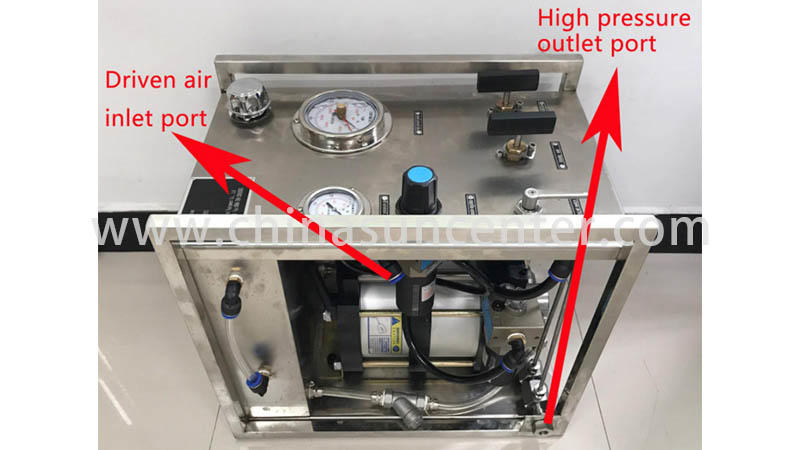

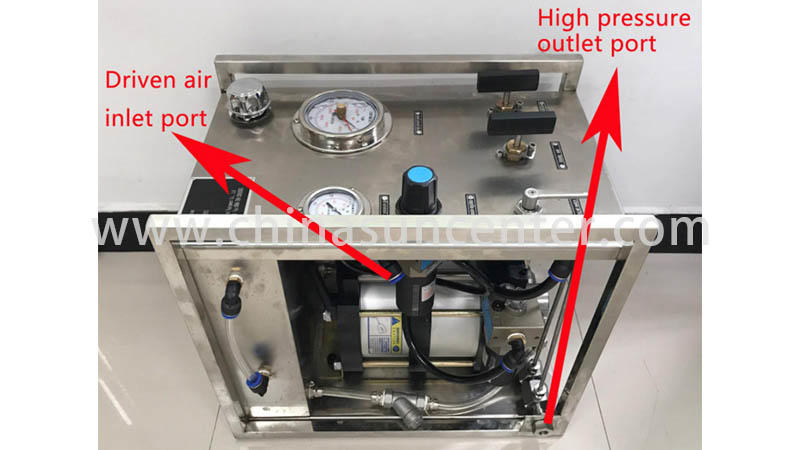

◪ The standard chemical injection pump system including following parts:

◪ Air –driven liquid booster pump (DGG/DGGD two series for choosing)

◪ Stainless steel (carbon steel) material cabinet (Three models for choosing)

◪ F.R.L combination for driven air (adjusts air pressure, add lubricating oil and water filter)

◪ Driven air switch (Pump starting switch), driven air pressure gauge, chemical(water) tank

◪ Liquid inlet/outlet switch, high pressure liquid guage, unloading valve, interconnecting pipes etc.

◪ And we could also customize it according to clients’ special requirement.

video

Copyright © 2025 Dongguan Suncenter Fluid Control Equipment Co., Ltd. | Tous droits réservés