Hydropneumatic Press machine

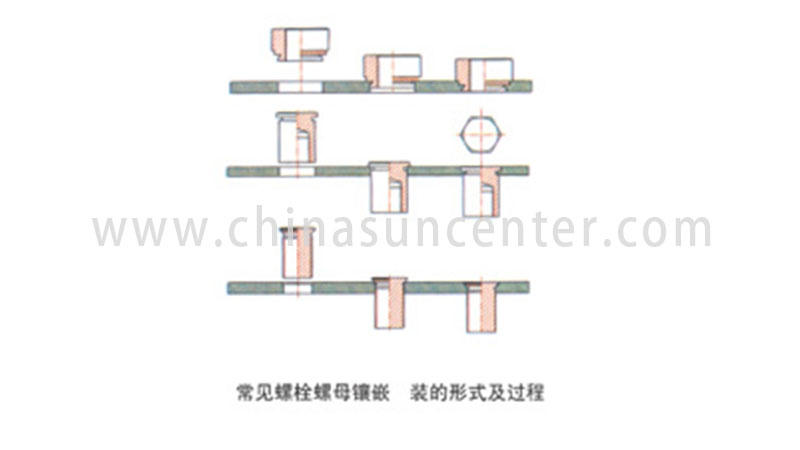

SSTPR04/SSTPR08 Model Bolt and nut riveting machine

Technology advantage:

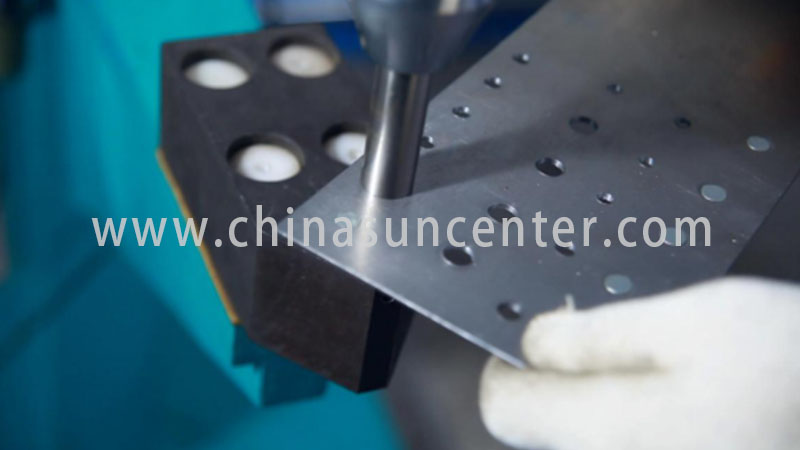

◪ Hydropneumatic booster cylinder unique soft technology in place and reinforcement adaptive technique to ensure pressing full mosaic of the nuts and bolts of the work piece, high reliability.

◪ The top resistance and torsion moment are high, and the quality of pressing can be detected automatically.

◪ Do not damage the paint layer on the surface of the work piece.

◪ No pressing deformation.

◪ Can be more points at the same time pressure, high efficiency, high degree of automation.

◪ Bolt and nut can be automatically sorted and transported, greatly improve work efficiency.

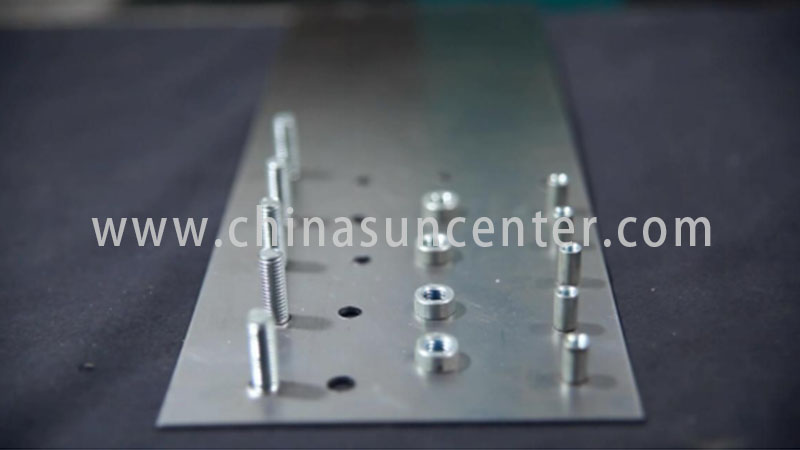

◪ Model SSTPR04 can be compressed with M10 below the nut and M5 the following bolts, such as the need to press the larger size of the bolt and nut, please select SSTPR08 Model

Technical parameter:

◪ Impact pressure 4.0T/8.0T - the power source of Hydropneumatic

◪ Voltage 50Hz 220V

◪ Total travel 100mm

◪ Compressed air source need:5-8 bar

◪ Weight 700Kg

◪ Pressing process:

video

Copyright © 2025 Dongguan Suncenter Fluid Control Equipment Co., Ltd. | Tous droits réservés