Pneumatic hydraulic oil cylinder

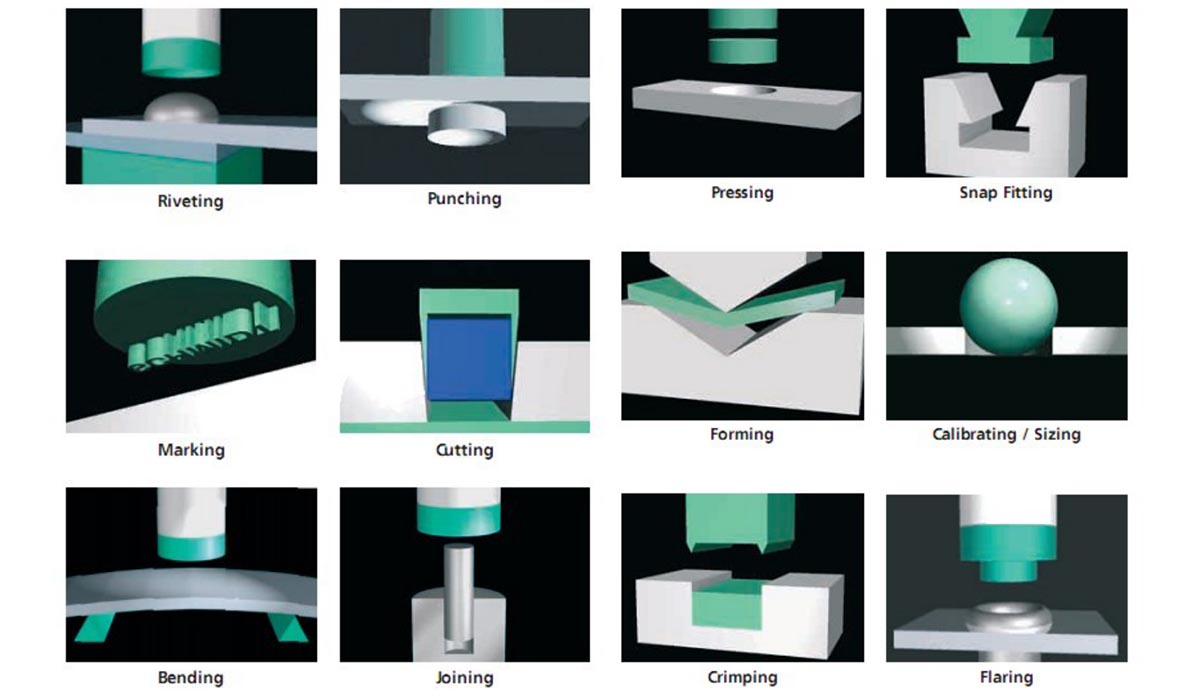

Hydro-pneumatic cylinder is the name of the new generation of power cylinders for press and plant engineering applications. The cylinder is used when high forces are required, for example for punching, splitting, pressing, stamping, molding, riveting, clamping, compressing or spot welding. In power stroke mode users are provided with many times the force of a comparable conventional pneumatic cylinder with the same air consumption.

Hydro-pneumatic cylinder is designed in the same way as a double-acting pneumatic cylinder and is also controlled in the same manner. It is equipped with a pneumohydraulic pressure booster which generates a power stroke when necessary depending on the counterforce. The power cylinder can be operated directly from the compressed air network by means of a pneumatic valve.

Simple operation

With its clever design the Hydro-pneumatic cylinder can be controlled in the same manner as a double-acting pneumatic cylinder. In contrast to conventional power cylinders, switchover from fast stroke to power stroke takes only approx. 0.05 seconds, without venting noises and without requiring an additional valve.

Tool-conserving operation

Positioning of the operating piston with the tool on the workpiece is extremely precise and therefore protects the tool, as only the surface of the piston rod is effective due to the design of the device with its freely-actuated operating piston.

On version SST-3T with a piston rod diameter of 20mm and a nominal pressure of 6 bar, for example, this contact force is 90kg; switchover from fast stroke to power stroke is therefore initiated at a counterforce of 90kg. The operating piston is hydraulically damped when it is pushed into the high-pressure sleeve and moves smoothly without jerking.

Switchover from fast stroke to power stroke is unnoticeable. While conventional pneumatic cylinders ,shoot through“ at full power, for example during punching operations, the Hydro-pneumatic cylinder gently makes contact with the workpiece with a low force and then builds up the full power.

Machining workpieces with varying heights does not pose a problem, as the power stroke is only generated when a corresponding counterforce is met at any position throughout the overall stroke.

Short flow path

The pressure booster and fluid reservoir are carried along during fast stroke and power stroke to ensure a favorable flow and hydraulic interaction.This enables the use of a highly viscous hydraulic oil which minimizes oil leakages.

The newly patented Hydro-pneumatic cylinder is an alternative to high-volume pneumatic systems, pure hydraulic systems and mechanical actuators. Various sizes are available for different power ranges and stroke lengths.

Practical Application

System technical parameters and composition

With its variable power stroke and fast stroke,the hydro-pneumatic cylinder is suitable for universal applications.the operating piston is extended in fast stroke mode until it makes contact with a counterforce.the power stroke is initiated when a specific counterforce – depending on the size of the device – is generated.the high-pressure sleeve is pushed further over operation piston.the high pressure chamber is closed and a high pressure builds up.

During this advance motion the oil is forced from the oil tank into the operating piston area.power stroke and fast stroke are interactive and form the operating range of the hydro-pneumatic cylinder.

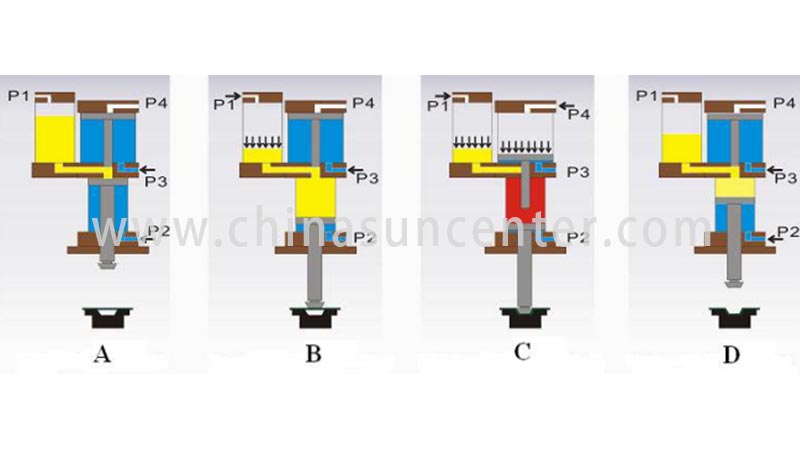

Working illustration

During this advance motion the oil is forced from the oil tank into the operating piston area.power stroke and fast stroke are interactive and form the operating range of the hydro-pneumatic cylinder.

◪ A:compressed air comes into P2 and P3.

◪ B:(fast stroke):compressed air comes into P1 and P3,P2 is on exhausting air state.air pressure acts on the hydraulic oil surface in the tank,then hydraulic oil drives the piston rod to touch workpiece.

◪ C:(power stroke) compressed air comes into P4,compressed air acts on the surface of piston,then piston rod moves to squeeze hydraulic oil,as oil can not be compressed,so high pressure oil pushes piston to press workpiece.

◪ D:(return stroke)compressed air comes into P2 ,P3 and P4 exhaust,hydraulic oil returns to tank and piston is lifted up.

Advantages

※ Operates only with air, without hydraulic power units

※ High travel stroke force, because of pressure applied to the working - and adjustment piston

※ Fast air-operated approach stroke and return stroke

※ Automatic change-over from approach stroke to power stroke

※ High stroke frequency, depending on the stroke length

※ Compact cylinder design, which can be used in any mounting position

Output force(Tonnages) | 1T / 3T / 5T /10 T /15T /20T / 30 T /40 T/ 50 T/ 60T/ 80T /100T |

Approach(Total) Stroke | 50 mm / 100 mm / 150mm / 200 mm/250mm/300mm |

Power(Hydraulic) Stroke | 5 mm / 10 mm/ 15mm / 20mm/ 25 mm |

Air Pressure Required | 3 bar-6 bar |

Air Quality | Filtered (40 Microns) Lubricated. |

video

Copyright © 2025 Dongguan Suncenter Fluid Control Equipment Co., Ltd. | Tous droits réservés